Choosing the Right 10 Ton Overhead Crane Supplier: What to Consider

Selecting the right 10 ton overhead crane supplier involves evaluating reliability, customization options, pricing, and after-sales support. Check now!

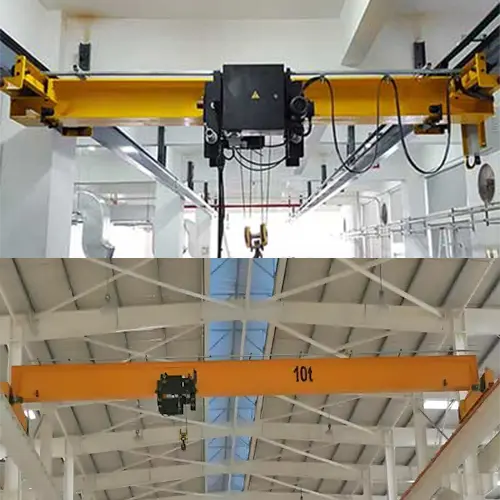

Category: 10 Ton Overhead Crane

Your Trusted 10 Ton Overhead Crane Manufacturer & Supplier

Choosing the Right 10 Ton Overhead Crane Supplier: What to Consider

Choosing the Right 10 Ton Overhead Crane Supplier: What to Consider

When it comes to industrial operations, selecting the right equipment supplier can make all the difference. This rings especially true when it comes to choosing a supplier for a 10-ton overhead crane. These machines are vital for lifting heavy loads efficiently and safely in various settings, from warehouses to construction sites. However, with numerous suppliers vying for your attention, making the right choice can be daunting.

Why Choosing the Right Supplier Matters

The supplier you choose plays a pivotal role in ensuring that your operations run smoothly. Opting for the wrong supplier can lead to delays, safety hazards, and unnecessary expenses. On the flip side, selecting a reliable and reputable supplier can enhance productivity, minimize downtime, and contribute to the overall success of your projects.

Know Your Requirements

Before to selecte a 10-ton overhead crane supplier, it's crucial to have a clear understanding of your specific needs and requirements. Here's how you can go about it:

Determining Your Specific Needs

Take some time to assess why you need a 10-ton overhead crane. What tasks will it be performing? What are the weight requirements for your lifting operations? By defining your needs upfront, you can narrow down your options and focus on suppliers who can meet your specific requirements.

Assessing Workload, Frequency of Use, and Operational Environment

Consider the demands of your workload and how frequently the crane will be in operation. Are you running a high-volume production facility with round-the-clock operations, or will the crane be used intermittently for smaller projects? Additionally, evaluate the operational environment, including factors such as temperature, humidity, and the presence of corrosive substances. This information will help you select a crane that can withstand the conditions it will be subjected to.

Identifying Specialized Features or Customizations Required

Every industry and application has its unique challenges and requirements. Identify any specialized features or customizations that may be necessary for your specific use case. This could include features such as extended reach, precision controls, or special lifting attachments. By pinpointing these requirements early on, you can ensure that the crane supplier you choose can accommodate your needs.

Understanding your requirements is the foundational step in the process of selecting the right 10-ton overhead crane supplier. By investing time and effort into this phase, you'll set yourself up for success and lay the groundwork for a productive partnership with your chosen supplier. So, take the time to assess your needs thoroughly before moving forward to the next steps.

Researching Potential Suppliers

Once you have a clear understanding of your requirements, the next step is to research potential suppliers who can meet those needs. Here's a detailed look at how you can go about it:

Online Search for Reputable Suppliers

Start by conducting an online search for reputable suppliers of 10-ton overhead cranes. Utilize search engines and industry-specific directories to identify companies that specialize in manufacturing and supplying overhead cranes. Pay attention to factors such as the company's reputation, years of experience, and customer reviews. Websites like industry forums and review platforms can provide valuable insights into the experiences of other customers.

Conducting an Online Search: Start your search by using popular search engines such as Google, Bing, or Yahoo. Use specific keywords like "10 Ton Overhead Crane suppliers," "reputable overhead crane manufacturers," or "best 10 Ton Overhead Crane brands." This will help you find companies that specialize in overhead cranes and have established themselves in the market.

Utilizing Industry-specific Directories: Industry-specific directories are valuable resources for finding reputable suppliers. Websites such as ThomasNet, Engineering360, and GlobalSpec offer comprehensive listings of suppliers categorized by product type and industry. These directories often provide detailed information about each company, including their contact details, product offerings, and customer reviews.

Evaluating Company Websites:

- Visit the websites of potential suppliers to gather more information. Look for the following key elements:

- Company History and Experience: Check how long the company has been in business and their experience in manufacturing overhead cranes. A long history and extensive experience often indicate reliability and expertise.

- Product Information: Review the specifications, features, and benefits of their 10-ton overhead cranes. Ensure they offer models that meet your specific requirements.

- Certifications and Standards: Verify if the company adheres to industry standards and holds relevant certifications, such as ISO 9001 for quality management.

- Case Studies and Testimonials: Look for case studies or customer testimonials that highlight successful installations and satisfied clients. This can provide insight into the company's track record and customer satisfaction.

Reading Customer Reviews: Customer reviews are invaluable for assessing the reputation of a supplier. Websites like Trustpilot, Yelp, and Google Reviews offer platforms where customers share their experiences. Pay attention to the overall rating and read through the reviews to understand common themes regarding product quality, customer service, and reliability.

Industry Forums and Review Platforms: Participate in industry forums and online communities where professionals discuss equipment and suppliers. Websites like Reddit, LinkedIn Groups, and specialized forums for material handling and manufacturing professionals can provide candid feedback and recommendations. Engage with other members to ask about their experiences and gather firsthand insights.

Checking Social Media: Social media platforms like LinkedIn, Facebook, and Twitter can also be useful. Follow or visit the pages of potential suppliers to see updates on their products, services, and customer interactions. Social media can also reveal how the company handles customer inquiries and complaints.

Verifying Contact Information and Communication: Ensure that the supplier provides clear and accessible contact information. Reliable suppliers should have multiple communication channels, including phone, email, and live chat. Reach out to them with preliminary inquiries to gauge their responsiveness and willingness to assist.

Requesting References: Don't hesitate to ask suppliers for references from previous clients. Speaking directly with other businesses that have purchased and used their cranes can provide detailed insights into the supplier's reliability, product quality, and customer service.

By leveraging these online resources and conducting a thorough search, you can compile a list of reputable suppliers for 10-ton overhead cranes. This foundational step sets the stage for a comprehensive evaluation and comparison process, ultimately leading to a well-informed purchasing decision.

Seeking Recommendations from Industry Peers or Associations

Reach out to your industry peers, colleagues, or contacts within relevant associations for recommendations on reputable crane suppliers. Networking with professionals who have firsthand experience with different suppliers can provide valuable insights and help you identify trustworthy options. Don't hesitate to ask for referrals or recommendations from those who have dealt with similar projects or requirements in the past.

When searching for reputable suppliers of 10-ton overhead cranes, leveraging the experience and insights of industry peers and associations can be incredibly beneficial. Here's how to effectively seek recommendations:

- Reaching Out to Industry Peers:

Colleagues and Contacts: Start by contacting colleagues within your organization who may have experience with crane suppliers. Their firsthand experience can provide valuable insights into the quality, reliability, and service of potential suppliers.

Professional Network: Utilize your professional network to gather recommendations. Connect with peers through platforms like LinkedIn, where you can join industry-specific groups or forums. Post inquiries asking for supplier recommendations and share your specific requirements to get more tailored advice.

- Attending Industry Events:

Trade Shows and Conferences: Attend trade shows, conferences, and exhibitions related to material handling, manufacturing, or construction. These events are excellent opportunities to network with industry professionals and discuss their experiences with different suppliers.

Workshops and Seminars: Participate in workshops and seminars where industry experts and seasoned professionals gather. These settings provide a platform for informal discussions and recommendations based on real-world experiences.

- Engaging with Industry Associations:

Membership Benefits: If you are a member of relevant industry associations, take advantage of the resources and networks they offer. Associations often have directories of trusted suppliers and can provide recommendations based on the collective experiences of their members.

Industry Reports and Publications: Associations frequently publish reports, buyer's guides, and newsletters that highlight reputable suppliers and recent developments in the industry. Review these publications for supplier recommendations and insights into market trends.

- Asking for Referrals:

Direct Referrals: When speaking with peers or contacts, ask for direct referrals to suppliers they have worked with. Inquire about their satisfaction with the product quality, customer service, and overall experience.

Testimonials: Request testimonials from your peers about specific suppliers. Written or verbal testimonials can provide a clearer picture of what to expect from a supplier, including potential challenges and benefits.

- Leveraging Online Communities:

Industry Forums: Participate in online forums and discussion boards related to material handling, construction, and manufacturing. Websites like Reddit, Quora, and specialized industry forums are valuable resources for gathering recommendations.

Social Media Groups: Join relevant groups on social media platforms such as LinkedIn and Facebook. These groups often have active discussions where members share their experiences and recommendations for various suppliers.

- Utilizing Professional Services:

Consulting Firms: Consider engaging with consulting firms that specialize in industrial equipment procurement. These firms often have extensive knowledge and connections within the industry and can recommend reliable suppliers based on your specific needs.

Procurement Services: If your organization uses procurement services, they can leverage their vendor networks to identify reputable suppliers. These services often have established relationships with trusted suppliers and can negotiate favorable terms

Reviewing Supplier Websites, Catalogs, and Product Specifications

Once you have a list of potential suppliers, take the time to review their websites, catalogs, and product specifications in detail. Look for information about the range of cranes they offer, including their capacity, features, and specifications. Pay attention to details such as materials used, safety features, and customization options. Additionally, explore their track record, certifications, and any relevant case studies or testimonials that demonstrate their expertise and reliability.

After compiling a list of potential suppliers for your 10-ton overhead crane, it's crucial to thoroughly review their online presence and available resources to make an informed decision. Here's how to effectively evaluate supplier websites, catalogs, and product specifications:

- Exploring Supplier Websites:

Product Range and Specifications: Examine the range of cranes offered by each supplier. Look for detailed product specifications, including load capacity, span, height of lift, duty cycle, and any additional features. Ensure the cranes meet your specific requirements.

Materials and Construction: Pay close attention to the materials used in the construction of the cranes. High-quality materials such as robust steel and durable components are indicative of a reliable and long-lasting product.

Safety Features: Review the safety features included in the crane designs. Features such as overload protection, emergency stop functions, and advanced control systems enhance the safety and reliability of the cranes.

Customization Options: Check if the supplier offers customization options. The ability to tailor the crane's specifications, dimensions, and additional features to your unique needs can significantly enhance its utility and efficiency in your operations.

- Reviewing Online Catalogs:

Comprehensive Product Listings: Download or request the supplier's product catalog. A detailed catalog should provide comprehensive information on each product, including technical specifications, application scenarios, and customization options.

Comparative Analysis: Use the catalogs to perform a side-by-side comparison of different models and their features. This helps in identifying which crane models best align with your operational needs and budget.

Visual Aids and Illustrations: Catalogs often include diagrams, images, and illustrations that give a clearer understanding of the crane's design, components, and functionalities. These visual aids can help you visualize how the crane will fit into your workspace.

- Examining Track Record and Certifications:

Company History and Experience: Review the company's history and experience in the crane manufacturing industry. A long-standing presence and a track record of successful installations can be indicators of reliability and expertise.

Certifications and Standards: Verify the certifications and standards the supplier adheres to, such as ISO 9001 for quality management or compliance with OSHA safety regulations. These certifications ensure the cranes meet industry standards for quality and safety.

Case Studies and Testimonials: Look for case studies and testimonials on the supplier's website. These provide real-world examples of how their cranes have been used successfully in similar applications. Testimonials from satisfied customers can offer insights into the supplier's reliability and customer service.

- Analyzing Product Specifications in Detail:

Technical Data Sheets: Download technical data sheets for the specific crane models you are interested in. These sheets should provide in-depth information on the crane's specifications, performance metrics, and operational limitations.

Performance Metrics: Pay attention to performance metrics such as lifting speed, duty cycle, and power consumption. These factors can impact the crane's efficiency and suitability for your specific application.

Maintenance and Support: Review the maintenance requirements and support services offered by the supplier. Understanding the maintenance needs and availability of spare parts and technical support is crucial for ensuring the long-term reliability of the crane.

- Assessing Website Usability and Professionalism:

Ease of Navigation: A well-organized and user-friendly website reflects the professionalism of the supplier. Ensure the website is easy to navigate, with clearly labeled sections and accessible information.

Content Quality: High-quality content, including detailed product descriptions, informative blog posts, and instructional videos, indicates the supplier's commitment to providing valuable information to customers.

Contact Information: Verify that the supplier provides clear and accessible contact information. Reliable suppliers should offer multiple communication channels, including phone, email, and live chat, to address your inquiries promptly.

By thoroughly reviewing supplier websites, catalogs, and product specifications, you can gather comprehensive information that will help you evaluate the suitability and reliability of each potential supplier. This meticulous approach ensures that you select a 10-ton overhead crane that meets your operational requirements, budget constraints, and quality standards, ultimately leading to a successful and satisfying purchase.

Evaluating Supplier Credentials

With a list of potential suppliers in hand, it's time to delve deeper into their credentials to ensure they meet your standards and requirements. Here's how you can effectively evaluate supplier credentials:

Verifying Supplier Experience in Manufacturing 10-Ton Overhead Cranes

Start by verifying the supplier's experience in manufacturing 10-ton overhead cranes. Look for evidence of their expertise in designing, engineering, and producing cranes that meet industry standards and customer needs. Check their track record for successful projects and inquire about their experience with projects similar to yours. A supplier with a proven history of manufacturing reliable and durable cranes is more likely to deliver quality products that meet your expectations.

Ensuring that a supplier has substantial experience in manufacturing 10-ton overhead cranes is critical to selecting a reliable partner. Here's how to verify a supplier's expertise and track record:

- Reviewing Company History and Background:

Establishment Date: Check when the company was founded. A longer history typically indicates stability and extensive experience in the industry.

Growth and Development: Look for information on the company's growth, milestones, and expansion. This can give you an idea of their market presence and evolution over time.

- Analyzing Product Portfolio:

Range of Products: Assess the variety of overhead cranes the supplier offers. A diverse product portfolio often indicates a broad understanding of different crane applications and customer needs.

Specialization in 10-Ton Cranes: Ensure that 10-ton overhead cranes are a significant part of their product line. Suppliers who specialize in this capacity are likely to have refined their designs and manufacturing processes for optimal performance.

- Examining Case Studies and Project Histories:

Successful Projects: Look for case studies or detailed project histories on the supplier's website. These should showcase examples of successful installations of 10-ton overhead cranes.

Similar Applications: Identify projects that are similar to your requirements. This includes the industry, operational environment, and specific needs. A supplier with experience in similar projects is more likely to understand and meet your expectations.

- Checking Certifications and Industry Standards:

ISO Certifications: Verify if the supplier holds ISO certifications, such as ISO 9001, which indicate adherence to quality management standards.

Compliance with Industry Standards: Ensure that the supplier's cranes meet industry-specific standards and regulations, such as those set by the Occupational Safety and Health Administration (OSHA) or the American Society of Mechanical Engineers (ASME).

- Seeking Testimonials and References:

Customer Testimonials: Read testimonials from previous customers, particularly those who purchased 10-ton overhead cranes. Positive feedback regarding product performance and supplier reliability is a good indicator of quality.

Direct References: Request direct references from the supplier. Speak with previous clients to get detailed feedback on their experiences, including product quality, installation process, and after-sales support.

- Assessing Engineering and Design Capabilities:

In-house Engineering Team: Verify if the supplier has an in-house engineering team dedicated to the design and development of overhead cranes. This suggests a strong capability to customize and optimize crane designs.

Design Innovations: Look for any innovations or unique design features that the supplier offers. These can indicate a commitment to improving crane performance and efficiency.

- Investigating Production Facilities:

Manufacturing Capabilities: Review information about the supplier's manufacturing facilities. Advanced production capabilities and modern equipment are indicative of a supplier's ability to produce high-quality cranes.

Quality Control Processes: Check for details on the supplier's quality control processes. Rigorous testing and inspection protocols ensure that each crane meets the required standards before delivery.

- Evaluating After-Sales Support and Service:

Maintenance and Repairs: Ensure the supplier offers comprehensive after-sales support, including maintenance and repair services. A supplier experienced in 10-ton cranes will have a well-established service network.

Availability of Spare Parts: Verify the availability of spare parts for their cranes. An experienced supplier will maintain an inventory of critical components to minimize downtime in case of repairs.

- Reviewing Awards and Recognitions:

Industry Awards: Check if the supplier has received any industry awards or recognitions. Awards for excellence in manufacturing, innovation, or customer service can be strong indicators of their expertise and reliability.

- Checking Online Presence and Reviews:

Website and Online Resources: A well-maintained website with comprehensive information on products, services, and company history reflects professionalism and transparency.

Independent Reviews: Look for reviews on independent platforms such as Trustpilot, Google Reviews, or industry-specific review sites. Consistent positive reviews from various customers strengthen the supplier's credibility.

By thoroughly verifying a supplier's experience in manufacturing 10-ton overhead cranes through these steps, you can confidently select a supplier with the proven expertise and reliability needed to meet your project's requirements and ensure a successful investment.

Checking for Certifications and Compliance with Industry Standards

Ensure that the supplier holds relevant certifications and complies with industry standards for overhead crane manufacturing. Look for certifications such as ISO 9001 for quality management systems and certifications specific to crane manufacturing, such as CE certification in Europe or ANSI/ASME standards in the United States. Compliance with industry standards ensures that the cranes meet safety, performance, and reliability requirements, giving you peace of mind in your procurement process.

Ensuring that a supplier holds relevant certifications and complies with industry standards is crucial when selecting a 10-ton overhead crane. Certifications and compliance indicate that the supplier adheres to recognized quality, safety, and performance benchmarks. Here's how to thoroughly check for these credentials:

- Identifying Key Certifications:

ISO 9001 Certification: Look for suppliers with ISO 9001 certification, which indicates that they maintain a quality management system meeting international standards. This certification ensures consistent product quality and continuous improvement processes.

ISO 14001 Certification: This certification demonstrates the supplier's commitment to environmental management, indicating they follow practices that minimize environmental impact.

ISO 45001 Certification: This certification focuses on occupational health and safety management systems, ensuring the supplier prioritizes workplace safety and risk management.

- Industry-Specific Certifications:

CE Marking (Europe): The CE marking indicates that the crane meets European Union safety, health, and environmental protection requirements. It is mandatory for products sold within the European Economic Area.

ANSI/ASME Standards (United States): Ensure the crane complies with standards set by the American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME). These standards cover design, manufacturing, testing, and maintenance of overhead cranes.

CSA Certification (Canada): The Canadian Standards Association (CSA) certification ensures compliance with Canadian safety and performance standards.

- Compliance with Safety Regulations:

OSHA Compliance: Verify that the supplier complies with Occupational Safety and Health Administration (OSHA) regulations. This ensures that the cranes meet U.S. workplace safety standards.

EN Standards (Europe): Check for compliance with European Norm (EN) standards, which cover various aspects of crane design, manufacturing, and safety.

- Verifying Certification Validity:

Request Certification Documents: Ask the supplier to provide copies of their certifications. Check the validity dates and ensure they are up-to-date.

Certification Bodies: Verify the credibility of the certification bodies. Reputable certification bodies include organizations such as TÜV, Lloyd's Register, and Bureau Veritas.

Online Verification: Some certification bodies offer online databases where you can verify the authenticity of the certificates provided by the supplier.

- Assessing Adherence to Industry Standards:

Standards Documentation: Review documentation or declarations from the supplier that detail compliance with relevant industry standards. This should cover aspects such as design criteria, manufacturing processes, and safety features.

Third-Party Audits: Check if the supplier undergoes regular third-party audits to ensure ongoing compliance with industry standards and certifications.

- Evaluating Manufacturing Processes:

Quality Control Procedures: Investigate the supplier's quality control procedures. A robust quality control system is essential for ensuring that cranes are manufactured to high standards and meet all regulatory requirements.

Testing and Inspection: Ensure that the supplier conducts comprehensive testing and inspection of their cranes. This includes load testing, structural inspections, and safety checks to verify that each crane meets the required standards before delivery.

- Checking for Additional Certifications:

Welding Certifications: Look for certifications related to welding quality, such as AWS (American Welding Society) certification. Proper welding is crucial for the structural integrity of overhead cranes.

Electrical Safety Standards: Ensure compliance with electrical safety standards, such as those set by the International Electrotechnical Commission (IEC) or Underwriters Laboratories (UL).

- Reviewing Supplier's Track Record:

Past Projects and Clients: Review the supplier's portfolio of past projects and clients. Successful completion of similar projects can indicate the supplier's ability to meet industry standards consistently.

Awards and Recognitions: Check if the supplier has received any industry awards or recognitions for their adherence to quality and safety standards.

- Consulting Industry Associations:

Industry Associations: Consult with industry associations or bodies related to crane manufacturing and material handling. They can provide insights into reputable suppliers and their compliance with industry standards.

By meticulously checking for certifications and compliance with industry standards, you ensure that the 10-ton overhead crane you procure will be safe, reliable, and of high quality. This due diligence provides peace of mind, knowing that the supplier adheres to the highest standards of manufacturing excellence.

Assessing Reputation Through Customer Reviews and Testimonials

One of the most reliable ways to gauge a supplier's reputation is by reviewing customer reviews and testimonials. Look for feedback from past customers regarding their experiences with the supplier, including aspects such as product quality, reliability, customer service, and after-sales support. Positive reviews and testimonials serve as endorsements of the supplier's credibility and ability to deliver on their promises. Conversely, negative feedback or complaints may indicate potential red flags that warrant further investigation.

Evaluating customer reviews and testimonials is an effective way to understand a supplier's reputation and reliability. Here's how to assess this feedback to make an informed decision about purchasing a 10-ton overhead crane:

- Identifying Reliable Review Sources:

Official Websites: Check the supplier's official website for customer testimonials and case studies. While these are often positive, they can provide insights into the supplier's strengths.

Independent Review Sites: Use independent review platforms like Trustpilot, Yelp, and Google Reviews. These sites often provide a more balanced view, including both positive and negative feedback.

Industry-Specific Forums: Participate in industry-specific forums and discussion boards where professionals share their experiences with various suppliers. Websites like Reddit, Quora, and specialized industry forums can offer candid feedback.

- Evaluating Product Quality and Reliability:

Customer Feedback on Product Performance: Look for reviews that specifically mention the performance of the 10-ton overhead cranes. Key aspects to consider include load handling, durability, and operational efficiency.

Consistency in Product Quality: Assess if multiple reviews consistently highlight the quality and reliability of the supplier's cranes. Consistency across different customers is a strong indicator of reliability.

- Analyzing Customer Service and Support:

Responsiveness: Pay attention to reviews mentioning the supplier's responsiveness to inquiries and issues. Prompt and helpful customer service is crucial for addressing any problems that may arise.

Technical Support: Look for feedback on the supplier's technical support capabilities. Efficient technical support can be a significant advantage, especially for complex machinery like overhead cranes.

After-Sales Service: Consider reviews that discuss after-sales services such as installation, maintenance, and repairs. Positive feedback in this area indicates strong ongoing support.

- Reviewing Specific Testimonials:

Detailed Testimonials: Focus on detailed testimonials that provide specific examples of the supplier's strengths and weaknesses. These testimonials often give a clearer picture of what to expect.

Case Studies: Review case studies provided by the supplier that highlight successful projects. Case studies that include metrics and detailed outcomes can provide valuable insights into the supplier's capabilities.

- Identifying Common Themes in Reviews:

Positive Themes: Look for recurring positive themes such as high-quality products, timely delivery, excellent customer service, and strong after-sales support. These themes suggest the supplier consistently meets customer expectations.

Negative Themes: Be aware of recurring negative themes, such as poor customer service, frequent product issues, delayed deliveries, or inadequate technical support. These may indicate potential problems.

- Investigating Negative Feedback:

Nature of Complaints: Examine the nature of negative feedback. Determine if the issues mentioned are deal-breakers or isolated incidents. Some complaints may be minor or related to specific circumstances.

Supplier's Response: Check how the supplier responds to negative reviews. A proactive and constructive response indicates a commitment to customer satisfaction and problem resolution.

- Seeking Direct References:

Requesting References: Ask the supplier for direct references from past customers. Speaking directly with previous clients can provide deeper insights into their experiences and satisfaction levels.

Inquiring About Similar Projects: Ensure the references provided include customers with projects similar to yours. Their experiences will be more relevant to your specific needs and requirements.

- Consulting Industry Professionals:

Industry Experts: Reach out to industry professionals or consultants who may have experience with the supplier. Their expert opinions can offer valuable perspectives on the supplier's reputation.

Peer Recommendations: Leverage your professional network to get recommendations and feedback. Personal endorsements from trusted colleagues can carry significant weight.

- Analyzing Social Media Presence:

Social Media Reviews: Check the supplier's social media profiles on platforms like LinkedIn, Facebook, and Twitter. Social media reviews and comments can provide additional insights into customer satisfaction and engagement.

Engagement and Responsiveness: Evaluate how the supplier engages with customers on social media. Active and responsive engagement is a positive sign of good customer relations.

- Compiling and Synthesizing Information:

Aggregating Feedback: Compile feedback from various sources to get a comprehensive view of the supplier's reputation. Consider both positive and negative reviews to form a balanced opinion.

Making an Informed Decision: Use the aggregated information to assess whether the supplier's reputation aligns with your expectations for product quality, reliability, and customer service.

By thoroughly assessing customer reviews and testimonials, you can gauge a supplier's reputation and make a well-informed decision. This due diligence helps ensure you select a supplier that is reliable, delivers high-quality products, and provides excellent customer support for your 10-ton overhead crane.

By evaluating supplier credentials through verifying their experience, checking for certifications, and assessing their reputation through customer reviews, you can make an informed decision about which supplier is best suited to meet your needs. Investing time and effort in this evaluation process will help you select a reliable partner who can provide you with high-quality overhead cranes and excellent service throughout your partnership.

Quality and Reliability of Products

Ensuring the quality and reliability of the overhead crane you choose is paramount to the safety and efficiency of your operations. Here's how you can assess these crucial aspects:

Examining the Materials and Construction Quality of Cranes

Start by examining the materials and construction quality of the cranes offered by the supplier. Look for sturdy construction using high-quality materials that can withstand heavy loads and harsh operating conditions. Check for features such as robust steel frames, durable hoists, and reliable electrical components. A well-built crane is more likely to deliver consistent performance and longevity, reducing the risk of downtime and maintenance issues.

When evaluating potential suppliers for a 10-ton overhead crane, it is crucial to examine the materials and construction quality of the cranes they offer. High-quality materials and robust construction are essential for ensuring the crane's durability, safety, and reliability. Here's how to assess these aspects effectively:

- Assessing Structural Materials:

Steel Quality: Ensure that the crane's main components, such as the girders and support structures, are made from high-grade steel. Look for materials with certifications indicating high tensile strength and resistance to corrosion and wear.

Weld Quality: Check the quality of the welding. High-quality, consistent welds are essential for structural integrity and load-bearing capacity. Poor welding can lead to weak points and potential failures under load.

- Evaluating the Frame and Support Structures:

Robust Frame Design: Examine the design of the crane's frame. It should be engineered to evenly distribute loads and minimize stress on individual components. Robust frames are less prone to deformation and can better handle the operational demands.

Reinforcements: Look for additional reinforcements in critical areas, such as load-bearing joints and connection points. These reinforcements add to the overall strength and stability of the crane.

- Inspecting Hoists and Lifting Mechanisms:

Durability of Hoists: Assess the quality of the hoists used in the crane. Durable hoists made from high-strength materials will perform reliably under continuous heavy use. Check if the hoists come from reputable manufacturers known for quality.

Lifting Chains or Cables: Inspect the lifting chains or cables. They should be made from high-grade steel or other durable materials that can withstand heavy loads without stretching or breaking.

Gearing and Drums: Ensure that the gearing and drums in the lifting mechanism are robust and well-machined. Precision manufacturing of these components contributes to smooth and reliable operation.

- Reviewing Electrical Components:

Control Systems: Check the quality of the electrical control systems. Reliable controls with advanced features can enhance safety and operational efficiency. Look for components that are weather-resistant and designed to operate in harsh conditions.

Motor and Drive Systems: Evaluate the motor and drive systems for their power, efficiency, and durability. High-quality motors are crucial for reliable lifting and movement operations.

- Analyzing Safety Features:

Overload Protection: Ensure the crane has robust overload protection systems to prevent lifting loads beyond its capacity. This feature protects both the crane and the operators from accidents.

Emergency Stop Mechanisms: Check for the presence of emergency stop mechanisms that allow operators to halt the crane's operation immediately in case of an emergency.

Safety Guards and Barriers: Look for safety guards and barriers around moving parts to prevent accidents and injuries. These should be designed to meet relevant safety standards.

- Considering Environmental and Operational Conditions:

Corrosion Resistance: For cranes operating in harsh environments, such as coastal areas or chemical plants, ensure that materials and coatings are resistant to corrosion. This includes galvanized steel components or special anti-corrosion treatments.

Temperature Tolerance: Assess the crane's ability to operate under extreme temperatures. Materials and components should be chosen to withstand the specific environmental conditions of your operation site.

- Checking Manufacturer's Specifications and Standards:

Technical Data Sheets: Review the technical data sheets provided by the manufacturer. These sheets should detail the materials used, construction methods, and performance specifications.

Compliance with Standards: Verify that the crane meets industry standards such as those set by the American Society of Mechanical Engineers (ASME), European Committee for Standardization (CEN), or other relevant bodies.

- Inspecting Samples or Visiting Production Facilities:

Sample Inspections: If possible, inspect sample cranes or components to directly assess the quality of materials and construction. This can provide a tangible sense of the product's robustness.

Factory Visits: Arrange visits to the supplier's production facilities. Observing the manufacturing processes firsthand can give you a better understanding of their quality control measures and overall production quality.

- Reviewing Supplier's Quality Control Processes:

Quality Assurance Programs: Check if the supplier has a comprehensive quality assurance program in place. This program should include regular inspections, testing, and certification of materials and finished products.

Third-Party Testing: Look for evidence of third-party testing and certification. Independent verification of quality can add an extra layer of assurance regarding the crane's construction and materials.

By meticulously examining the materials and construction quality of the cranes offered by potential suppliers, you ensure that you select a crane that is built to last, safe to operate, and capable of meeting the demands of your specific application. This thorough evaluation helps minimize the risk of downtime and maintenance issues, leading to a more reliable and efficient operation.

Assessing Safety Features and Compliance with Regulations

Safety should always be a top priority when selecting an overhead crane supplier. Assess the safety features incorporated into the crane design, such as overload protection, emergency stop buttons, and anti-collision systems. Ensure that the cranes comply with relevant safety regulations and standards set by organizations such as OSHA (Occupational Safety and Health Administration) or ANSI (American National Standards Institute). Choosing a supplier that prioritizes safety not only protects your workers but also minimizes the risk of accidents and liabilities.

When selecting an overhead crane supplier, prioritizing safety is essential. A crane equipped with advanced safety features and compliant with relevant safety regulations ensures the protection of your workforce and minimizes the risk of accidents. Here's how to assess the safety features and regulatory compliance of potential suppliers:

- Evaluating Key Safety Features:

Overload Protection Systems: Ensure that the crane is equipped with overload protection systems that prevent the crane from lifting loads beyond its capacity. This feature is critical for avoiding mechanical failures and accidents.

Emergency Stop Buttons: Check for the presence of emergency stop buttons that allow operators to quickly halt crane operations in case of an emergency. These should be easily accessible and strategically placed.

Anti-Collision Systems: Look for cranes with anti-collision systems that prevent the crane from colliding with other equipment or structures. These systems use sensors and automated controls to enhance operational safety.

Limit Switches: Verify that the crane has limit switches installed to prevent it from traveling beyond its designated path or lifting beyond a certain height. These switches protect against mechanical overextension and potential damage.

Safety Guards and Barriers: Ensure that the crane has safety guards and barriers around moving parts to protect operators from accidental contact. These should meet industry safety standards and be robust enough to withstand daily operations.

Fail-Safe Mechanisms: Check for fail-safe mechanisms that automatically engage in the event of a power failure or system malfunction. These mechanisms ensure that the crane can be safely stopped and secured during an emergency.

- Ensuring Compliance with Safety Regulations:

OSHA Regulations (U.S.): Verify that the crane complies with OSHA regulations, which set standards for safe crane operation, maintenance, and training in the United States. Compliance with OSHA standards ensures that the crane meets essential safety requirements.

ANSI Standards (U.S.): Ensure compliance with ANSI standards, particularly those related to crane design, manufacturing, and operation. ANSI standards provide guidelines for safe and efficient crane performance.

EN Standards (Europe): For cranes used in Europe, check compliance with European Norm (EN) standards. These standards cover various aspects of crane safety, including design, manufacturing, and testing.

ISO Standards: Look for compliance with ISO standards, such as ISO 9927 for the inspection and maintenance of cranes, and ISO 4301 for crane classification based on usage and operating conditions.

Local Regulations: Ensure that the crane complies with any additional local regulations and safety standards relevant to your region or industry. Local regulations may have specific requirements that need to be met.

- Reviewing Manufacturer's Safety Certifications:

Certification Documents: Request copies of the supplier's safety certifications. These documents should confirm compliance with relevant safety standards and regulations.

Third-Party Certifications: Look for certifications from reputable third-party organizations that specialize in safety and quality assurance. Certifications from entities like TÜV, Lloyd's Register, or Bureau Veritas add credibility to the supplier's safety claims.

- Analyzing Safety Track Record:

Accident and Incident Reports: Inquire about the supplier's safety track record, including any history of accidents or incidents involving their cranes. A good safety record indicates a commitment to safety and reliable product performance.

Customer Testimonials: Review customer testimonials that specifically mention safety aspects. Positive feedback regarding the crane's safety features and performance can provide reassurance.

- Consulting Industry Experts and Peers:

Industry Associations: Engage with industry associations or bodies related to crane manufacturing and operation. These organizations can provide insights into reputable suppliers and their adherence to safety standards.

Peer Recommendations: Seek recommendations from peers or colleagues who have experience with similar cranes. Their firsthand experiences can offer valuable perspectives on the supplier's commitment to safety.

- Inspecting Safety Features in Person:

On-Site Visits: If possible, arrange for on-site visits to see the cranes in operation. Observing the safety features firsthand and speaking with operators can provide practical insights into the crane's safety and functionality.

Supplier Demonstrations: Request demonstrations from the supplier to showcase the crane's safety features in action. This allows you to see how the safety mechanisms work and how easily they can be operated by your team.

- Reviewing Maintenance and Safety Protocols:

Maintenance Plans: Assess the supplier's maintenance plans and protocols. Regular maintenance is crucial for ensuring that safety features remain effective and the crane operates safely over its lifespan.

Training Programs: Check if the supplier offers training programs for operators and maintenance personnel. Proper training ensures that your team understands how to safely operate and maintain the crane.

- Understanding Warranty and Support:

Warranty Coverage: Ensure that the crane's warranty covers safety components and systems. A comprehensive warranty indicates the supplier's confidence in their product's safety and reliability.

After-Sales Support: Evaluate the level of after-sales support provided by the supplier. Effective support can address any safety concerns or issues that arise after installation.

By thoroughly assessing the safety features and compliance with regulations of potential crane suppliers, you can ensure that you select a crane that prioritizes the well-being of your workforce and meets all necessary safety standards. This diligence not only protects your employees but also minimizes the risk of operational disruptions and liabilities, contributing to a safer and more productive work environment.

Evaluating Product Warranties and After-Sales Support

Review the product warranties offered by the supplier to understand the level of protection and support provided for your investment. A comprehensive warranty reflects the supplier's confidence in the quality and reliability of their products. Additionally, inquire about the after-sales support services available, such as maintenance, repairs, and technical assistance. A supplier that offers prompt and responsive after-sales support ensures that any issues or concerns are addressed promptly, minimizing downtime and disruptions to your operations.

When considering an overhead crane supplier, it's essential to review the product warranties and after-sales support services offered. These aspects provide insight into the level of protection and assistance you can expect after making your investment. Here's how to evaluate product warranties and after-sales support effectively:

- Reviewing Product Warranties:

Coverage Period: Examine the duration of the warranty coverage offered by the supplier. Longer warranty periods typically indicate the supplier's confidence in the quality and reliability of their products.

Scope of Coverage: Determine what components and aspects of the crane are covered under the warranty. This may include structural components, electrical systems, and mechanical parts. Ensure that essential safety features are also included.

Exclusions and Limitations: Pay attention to any exclusions or limitations specified in the warranty terms. Understand what circumstances may void the warranty and what actions are required to maintain coverage.

Transferability: Check if the warranty is transferable to subsequent owners. A transferable warranty can enhance the crane's resale value and provide peace of mind to future buyers.

- Assessing After-Sales Support Services:

Maintenance Services: Inquire about the maintenance services offered by the supplier. Regular maintenance is crucial for ensuring the crane's continued performance and longevity. Ask about scheduled maintenance plans and frequency.

Repair Services: Determine the availability of repair services for addressing any mechanical or electrical issues that may arise during the crane's lifespan. Prompt repairs minimize downtime and prevent disruptions to operations.

Technical Assistance: Evaluate the supplier's provision of technical assistance and support. This may include phone support, on-site troubleshooting, and remote diagnostics to address operational challenges effectively.

Spare Parts Availability: Ensure that the supplier maintains an inventory of spare parts for the crane. Availability of genuine replacement parts reduces lead times for repairs and ensures compatibility with the crane's components.

Emergency Response: Inquire about the supplier's emergency response capabilities. Understand how quickly they can mobilize support personnel and resources in the event of critical failures or emergencies.

- Understanding Service Level Agreements (SLAs):

Response Times: Clarify the expected response times for after-sales support requests. This includes acknowledgment of service requests, on-site visits for inspections or repairs, and resolution of issues.

Resolution Procedures: Understand the procedures for escalating support requests and resolving complex issues. Clear escalation paths ensure that critical issues receive appropriate attention and priority handling.

Performance Metrics: Establish performance metrics and service level agreements (SLAs) to measure the supplier's adherence to service standards. These metrics may include response times, resolution times, and customer satisfaction scores.

- Evaluating Support Resources and Expertise:

Qualified Technicians: Ensure that the supplier employs qualified technicians and engineers with expertise in overhead crane maintenance and repair. Experienced personnel can diagnose and resolve issues efficiently, minimizing downtime.

Training Programs: Inquire about training programs offered by the supplier for crane operators and maintenance personnel. Proper training ensures that your team can effectively operate and maintain the crane, reducing the risk of accidents and errors.

- Checking Customer Satisfaction and References:

Customer Feedback: Seek feedback from existing customers regarding their experiences with the supplier's after-sales support services. Positive testimonials indicate the supplier's commitment to customer satisfaction and support.

References: Request references from the supplier and contact them to inquire about their satisfaction with the after-sales support received. Direct references provide valuable insights into the supplier's reliability and responsiveness.

- Negotiating Service Contracts and Agreements:

Customized Contracts: Discuss options for customizing service contracts and agreements to align with your specific needs and operational requirements. Tailored contracts ensure that you receive the level of support necessary for your crane operations.

Cost Considerations: Evaluate the cost implications of after-sales support services and factor them into your overall procurement decision. Balance the cost with the value provided by the supplier's support offerings.

- Assessing Supplier's Track Record:

Track Record: Consider the supplier's track record in delivering reliable after-sales support services. Review their history of customer satisfaction, response times, and resolution of issues to gauge their performance.

Industry Reputation: Assess the supplier's reputation within the industry for their commitment to after-sales support and customer service excellence.

- Clarifying Communication Channels and Procedures:

Communication Channels: Establish clear communication channels and procedures for initiating and tracking after-sales support requests. Ensure that you have direct contact information for support personnel and escalation points if needed.

By thoroughly evaluating product warranties and after-sales support services, you can ensure that you choose a supplier who stands behind their products and provides the necessary assistance to keep your operations running smoothly. This proactive approach minimizes disruptions, maximizes uptime, and protects your investment in an overhead crane.

By examining the materials and construction quality, assessing safety features and compliance with regulations, and evaluating product warranties and after-sales support, you can make an informed decision about the quality and reliability of the overhead crane supplied by a particular vendor. Prioritizing these factors ensures that you invest in a crane that meets your performance requirements while prioritizing the safety and well-being of your workforce.

Cost Considerations

While cost is a significant factor in any procurement decision, it's essential to strike a balance between upfront expenses and long-term value. Here's how you can approach cost considerations when choosing an overhead crane supplier:

Comparing Pricing Among Different Suppliers

Begin by gathering pricing information from multiple suppliers to compare their offerings. While it's tempting to opt for the lowest-priced option, keep in mind that quality and reliability should not be sacrificed for upfront savings. Look for suppliers that offer competitive pricing while still meeting your requirements for quality, reliability, and after-sales support. Consider requesting detailed quotes that itemize costs to ensure transparency and avoid hidden fees or surprises down the line.

When embarking on the process of selecting an overhead crane supplier, comparing pricing among different suppliers is a critical step. However, it's essential to approach this task with careful consideration, balancing cost-effectiveness with the quality, reliability, and after-sales support that your project demands. Here's a detailed approach to comparing pricing:

- Gathering Pricing Information:

Request Quotes: Reach out to multiple suppliers to gather pricing information for the overhead crane you require. Provide detailed specifications to ensure accurate quotes.

Online Research: Utilize supplier websites, industry directories, and online platforms to gather initial pricing estimates. However, note that these estimates may vary based on customization and other factors.

Industry Contacts: Engage with industry contacts or associations to obtain insights into typical pricing ranges for overhead cranes. This can help you gauge whether the quotes you receive are competitive.

- Considering Total Cost of Ownership (TCO):

Initial Cost vs. Long-Term Costs: Evaluate the total cost of ownership (TCO) rather than focusing solely on the initial purchase price. Consider factors such as maintenance, repairs, downtime, and energy consumption over the crane's lifespan.

Lifecycle Cost Analysis: Conduct a lifecycle cost analysis to compare the overall costs of each supplier's offering over the crane's expected lifespan. This analysis provides a more comprehensive understanding of the true cost implications.

- Balancing Price with Quality and Reliability:

Avoiding Lowest Price Trap: While a low price may be attractive, prioritize quality and reliability over upfront savings. A lower-priced crane may compromise on materials, construction, or safety features, leading to higher long-term costs and risks.

Assessing Value Proposition: Evaluate the value proposition offered by each supplier. Consider factors such as reputation, track record, warranty terms, and after-sales support when assessing the overall value of their offering.

- Requesting Detailed Quotes:

Itemized Quotes: Request detailed, itemized quotes from each supplier to understand the breakdown of costs. This transparency helps identify any hidden fees or discrepancies between quotes.

Clarify Inclusions and Exclusions: Ensure that each quote clearly specifies what is included in the price and any items or services that may be excluded. This prevents misunderstandings and ensures you are comparing apples to apples.

- Negotiating Pricing and Terms:

Negotiation Strategies: Use the pricing information gathered to negotiate with suppliers for competitive rates. Consider negotiating bulk discounts, payment terms, or value-added services to improve the overall deal.

Flexibility: Be open to exploring flexible pricing and payment options that align with your budget constraints and project timeline.

- Assessing After-Sales Support:

Factor in After-Sales Costs: Consider the after-sales support offered by each supplier when evaluating pricing. A supplier that provides comprehensive after-sales support may offer better long-term value despite higher upfront costs.

Warranty Considerations: Assess the warranty terms offered by each supplier and factor them into your cost analysis. A robust warranty can provide added protection and minimize future expenses.

- Evaluating Supplier Reputation:

Supplier Track Record: Consider the reputation and track record of each supplier when assessing their pricing. A supplier with a proven history of delivering high-quality products and reliable service may justify a higher price.

Customer Feedback: Review customer testimonials and references to gauge satisfaction levels with each supplier's pricing, product quality, and service.

- Aligning Pricing with Project Requirements:

Customization Needs: Consider any customization or special requirements for your project when evaluating pricing. Suppliers that can accommodate your specific needs may offer added value despite slightly higher costs.

Scalability: Assess how well each supplier's pricing aligns with the scalability of your project. Ensure that the chosen supplier can meet your current needs and accommodate future growth or changes.

- Decision-Making Process:

Holistic Evaluation: Conduct a holistic evaluation of each supplier's pricing in conjunction with other factors such as quality, reliability, and after-sales support. Choose the supplier that offers the best overall value proposition for your project needs.

Risk Assessment: Consider the risks associated with each pricing option and weigh them against potential benefits. Prioritize minimizing risks while maximizing value in your final decision.

By systematically comparing pricing among different suppliers and considering the broader context of quality, reliability, and after-sales support, you can make an informed decision that optimizes both cost-effectiveness and project success. This approach ensures that your investment in an overhead crane delivers long-term value and performance for your operations.

Assessing Total Cost of Ownership, Including Maintenance and Repair Expenses

Beyond the initial purchase price, consider the total cost of ownership over the crane's lifespan. Factor in ongoing expenses such as maintenance, repairs, and spare parts. A higher-quality crane may have a slightly higher upfront cost but could result in lower maintenance and repair expenses over time. Additionally, assess the expected lifespan of the crane and the potential for future upgrades or modifications. By taking a holistic view of the total cost of ownership, you can make a more informed decision that maximizes value in the long run.

When evaluating overhead crane options, it's crucial to look beyond the initial purchase price and consider the total cost of ownership (TCO) over the crane's lifespan. This holistic approach takes into account ongoing expenses such as maintenance, repairs, and spare parts, providing a more accurate picture of the crane's long-term affordability and value. Here's how to assess the total cost of ownership effectively:

- Evaluating Maintenance and Repair Expenses:

Scheduled Maintenance Costs: Inquire about the cost of scheduled maintenance services recommended by the supplier. Regular maintenance helps prevent breakdowns and prolongs the crane's lifespan.

Repair Service Fees: Assess the potential costs associated with unexpected repairs or breakdowns. Consider factors such as labor rates, replacement parts, and service call fees.

Availability of Spare Parts: Evaluate the availability and cost of spare parts for the crane. Ensure that genuine replacement parts are readily accessible to minimize downtime and maintain optimal performance.

Warranty Coverage: Consider the extent of warranty coverage for maintenance and repairs provided by the supplier. A comprehensive warranty can reduce out-of-pocket expenses for covered services.

- Comparing Maintenance Requirements:

Maintenance Intervals: Compare the recommended maintenance intervals for different crane models. A crane with longer maintenance intervals may incur lower ongoing costs compared to one that requires frequent servicing.

Ease of Maintenance: Assess the ease of performing maintenance tasks on each crane model. Cranes with accessible components and user-friendly maintenance procedures may result in lower labor costs for maintenance activities.

- Anticipating Lifecycle Costs:

Projected Lifespan: Consider the expected lifespan of each crane model based on its design, construction, and usage. A crane with a longer projected lifespan may offer better value over time, even if it has a higher upfront cost.

Lifecycle Cost Analysis: Conduct a lifecycle cost analysis to compare the total cost of ownership for each crane option. Factor in all anticipated expenses over the crane's lifespan to determine the most cost-effective choice.

- Assessing Quality and Reliability:

Impact on Maintenance Costs: Consider how the quality and reliability of each crane model may affect maintenance and repair expenses. Higher-quality cranes often require fewer repairs and less frequent maintenance, resulting in lower overall costs.

Supplier Reputation: Evaluate the reputation of each supplier for producing durable, reliable cranes with minimal maintenance requirements. Choose a supplier with a track record of delivering high-quality products to mitigate future maintenance expenses.

- Factoring in Upgrades and Modifications:

Future Expansion Needs: Anticipate any future upgrades or modifications that may be required to accommodate changes in your operations or facility layout. Assess the potential costs of these upgrades when calculating the total cost of ownership.

Compatibility with Upgrades: Choose a crane model that offers compatibility with common upgrades and modifications to minimize retrofitting costs in the future.

- Considering Energy Efficiency:

Energy Consumption: Evaluate the energy efficiency of each crane model and its potential impact on operating costs. Cranes with energy-efficient components and design features may result in lower electricity bills over time.

Environmental Impact: Consider the environmental benefits of choosing a more energy-efficient crane, including reduced carbon emissions and resource conservation.

- Accounting for Downtime and Productivity Losses:

Impact of Downtime: Assess the potential financial impact of crane downtime on your operations, including lost productivity, missed deadlines, and potential penalties. Choose a crane model with a reliable track record to minimize the risk of unplanned downtime.

Supplier Response Time: Consider the supplier's response time for addressing maintenance and repair issues. A supplier with prompt and efficient service capabilities can help minimize downtime and mitigate associated costs.

- Negotiating Service Contracts and Warranties:

Comprehensive Service Agreements: Negotiate comprehensive service agreements with suppliers to cover maintenance, repairs, and spare parts. Clarify the terms, coverage, and costs associated with these agreements to ensure alignment with your budget and requirements.

Extended Warranty Options: Explore extended warranty options offered by suppliers to provide additional protection against unforeseen maintenance and repair expenses.

- Long-Term Value vs. Short-Term Savings:

Balancing Cost and Quality: Strike a balance between upfront cost savings and long-term value when selecting an overhead crane. Avoid sacrificing quality and reliability for short-term savings, as this may result in higher total cost of ownership over time.

ROI Considerations: Evaluate the return on investment (ROI) for each crane option, considering both upfront costs and anticipated savings in maintenance and repair expenses. Choose the option that offers the best overall ROI for your organization.

By carefully assessing the total cost of ownership, including maintenance and repair expenses, you can make a more informed decision when selecting an overhead crane. Prioritize long-term value and reliability to ensure optimal performance and cost-effectiveness over the crane's lifespan, ultimately enhancing the efficiency and profitability of your operations.

Avoiding Overly Cheap Options That May Compromise on Quality

Be wary of overly cheap options that seem too good to be true. While low-priced cranes may appear attractive initially, they often come with compromises in quality, reliability, and safety. Cutting corners on materials, construction, or safety features can lead to increased downtime, higher maintenance costs, and safety risks for your workforce. Instead, prioritize suppliers that offer competitive pricing without compromising on essential factors such as product quality, safety, and after-sales support.

When considering overhead crane options, it's essential to exercise caution when encountering excessively cheap offerings that seem too good to pass up. While the allure of a low price may be tempting, it often comes at the expense of quality, reliability, and safety. Here are key points to keep in mind to avoid compromising on crucial factors when evaluating crane options:

- Quality and Reliability Concerns:

Material and Construction Quality: Cheaper cranes may cut corners by using lower-quality materials and substandard construction techniques. This compromises the structural integrity and durability of the crane, leading to premature wear and potential failures.

Component Reliability: Inferior components and mechanical parts in low-priced cranes are more prone to malfunction and breakdowns, resulting in increased downtime and maintenance costs over time.

Long-Term Performance: Consider the long-term performance implications of opting for a cheap crane. The initial cost savings may pale in comparison to the expenses incurred due to frequent repairs, replacements, and operational disruptions.

- Safety Risks and Compliance Issues:

Safety Features and Standards: Cheap cranes often skimp on essential safety features and may not fully comply with industry standards and regulations. This poses significant safety risks to your workforce and increases the likelihood of accidents and injuries.

Overload and Failure Risks: Inadequate design and construction of low-priced cranes increase the risk of overloading, structural failure, and operational hazards. Prioritizing safety is paramount to protect personnel and assets from harm.

- Hidden Costs and Unforeseen Expenses:

Maintenance and Repairs: While the initial purchase price may be low, cheap cranes often incur higher maintenance and repair costs due to frequent breakdowns and component failures. These hidden costs can quickly offset any upfront savings.

Downtime and Productivity Losses: Operational disruptions caused by unreliable cranes result in lost productivity, missed deadlines, and potential penalties. The financial impact of downtime far outweighs any initial cost savings.

- Importance of After-Sales Support:

Limited Support and Service: Suppliers of cheap cranes may offer minimal after-sales support, leaving you stranded when issues arise. Lack of technical assistance, spare parts availability, and repair services further exacerbate maintenance challenges.

Value of Comprehensive Support: Prioritize suppliers that provide comprehensive after-sales support, including maintenance, repairs, and technical assistance. Investing in reliable support ensures timely resolution of issues and minimal downtime.

- Long-Term Investment Perspective:

Total Cost of Ownership: Take a holistic view of the total cost of ownership when evaluating crane options. While a cheap crane may seem cost-effective initially, its inferior quality and performance result in higher expenses over its lifespan.

ROI and Value Proposition: Consider the return on investment (ROI) and overall value proposition of each crane option. Quality cranes from reputable suppliers offer superior ROI by delivering long-term reliability, safety, and operational efficiency.

- Supplier Reputation and Track Record:

Reputable Suppliers: Prioritize suppliers with a proven track record of delivering high-quality, reliable cranes. Established manufacturers with a reputation for excellence are more likely to offer competitive pricing without compromising on quality.

Customer Reviews and Testimonials: Research customer reviews and testimonials to gauge the satisfaction levels of previous buyers. Positive feedback regarding product quality, performance, and after-sales support validates the supplier's credibility.

- Making Informed Decisions:

Due Diligence: Conduct thorough research and due diligence before making a purchasing decision. Evaluate multiple crane options, compare pricing, and scrutinize product specifications to make an informed choice.

Consultation and Expert Advice: Seek advice from industry experts, consultants, and peers to gain valuable insights into the best crane options for your specific needs. Their experience and expertise can help you navigate the decision-making process effectively.

- Prioritizing Value Over Price:

Quality Over Price: Ultimately, prioritize value over price when selecting an overhead crane. Investing in a high-quality, reliable crane may entail a higher initial cost, but it delivers superior long-term performance, safety, and peace of mind.

Cost-Effectiveness: Focus on cost-effectiveness rather than chasing the lowest price. A crane that meets your requirements for quality, reliability, safety, and after-sales support offers the best value proposition in the long run.

By avoiding overly cheap options that compromise on quality, you safeguard your investment and ensure the safety and productivity of your operations. Prioritize suppliers that offer competitive pricing without sacrificing essential factors such as product quality, safety, and after-sales support, thereby maximizing the value and performance of your overhead crane solution.

By comparing pricing among different suppliers, assessing the total cost of ownership, and avoiding overly cheap options that may compromise on quality, you can make a cost-effective decision that aligns with your budget while ensuring the reliability and safety of your overhead crane investment. Remember to prioritize long-term value over short-term savings to maximize the return on your investment and minimize potential risks and expenses.

Customer Service and Support

Effective customer service and support are essential elements of a successful partnership with an overhead crane supplier. Here's how you can evaluate and prioritize these aspects:

Evaluating Supplier Responsiveness to Inquiries and Concerns

Begin by assessing the supplier's responsiveness to inquiries and concerns during the initial stages of communication. Pay attention to how promptly they respond to your queries and the level of detail provided in their responses. A supplier that values open communication and promptly addresses your concerns demonstrates a commitment to customer satisfaction and is more likely to provide reliable support throughout your partnership.

Assessing the Availability of Technical Support and Assistance

Technical support plays a crucial role in ensuring the smooth operation of your overhead crane system. Evaluate the availability and accessibility of technical support offered by the supplier. Inquire about the availability of knowledgeable support staff who can assist with installation, troubleshooting, and maintenance tasks. Additionally, assess the responsiveness of the technical support team and their ability to address issues promptly to minimize downtime and disruptions to your operations.

Considering Proximity for Efficient Communication and Service

Consider the geographical proximity of the supplier's facilities and service centers to your location. Opting for a supplier with nearby service centers can facilitate more efficient communication, faster response times, and reduced travel costs for on-site support and maintenance visits. However, prioritize proximity alongside other factors such as product quality and support capabilities to ensure a well-rounded decision that meets your needs.

By evaluating the supplier's responsiveness to inquiries and concerns, assessing the availability of technical support and assistance, and considering proximity for efficient communication and service, you can ensure that you partner with a supplier who prioritizes customer satisfaction and provides reliable support throughout your relationship. Effective customer service and support are critical for maximizing the performance, reliability, and longevity of your overhead crane system, making them essential factors to consider in your decision-making process.

Customization Options

Every industrial operation is unique, and having the flexibility to customize your overhead crane solution to meet specific requirements is invaluable. Here's how you can assess a supplier's customization capabilities and ensure they can accommodate your evolving needs:

Assessing the Supplier's Capability to Tailor Solutions to Specific Needs

Begin by evaluating the supplier's capability to tailor overhead crane solutions to your specific needs. Inquire about their experience and expertise in customizing cranes for unique applications, such as specialized lifting requirements or challenging operating environments. A supplier that demonstrates a willingness and ability to understand your unique requirements and develop tailored solutions is more likely to deliver a crane that meets your exact specifications and enhances the efficiency of your operations.

Evaluating Past Customization Projects and Their Success

Review the supplier's portfolio of past customization projects to assess their track record and success in delivering tailored solutions to customers. Look for case studies or testimonials that highlight their experience in customizing cranes for diverse industries and applications. Pay attention to the outcomes of these projects, including improvements in productivity, efficiency, and safety achieved through customization. A supplier with a proven history of successful customization projects demonstrates their ability to innovate and adapt to meet customer needs effectively.

Determining Flexibility in Accommodating Future Changes or Upgrades

Consider the supplier's flexibility in accommodating future changes or upgrades to your overhead crane system. Inquire about their ability to incorporate additional features, expand capacity, or integrate new technologies as your operational requirements evolve. A supplier that offers flexibility and scalability in their solutions ensures that your investment remains future-proof and adaptable to changing needs, minimizing the need for costly replacements or upgrades down the line.

By assessing the supplier's capability to tailor solutions to specific needs, evaluating their past customization projects and success, and determining their flexibility in accommodating future changes or upgrades, you can ensure that you partner with a supplier who can deliver customized overhead crane solutions that align with your unique requirements and support your long-term growth and success. Customization options provide the flexibility to optimize crane performance and adapt to evolving operational needs, making them essential considerations in your selection process.

Delivery Time and Logistics

Timely delivery and efficient logistics are crucial factors in ensuring that your overhead crane system is installed and operational when you need it. Here's how you can manage delivery time and logistics effectively:

Inquiring About Lead Times and Delivery Schedules